Technology

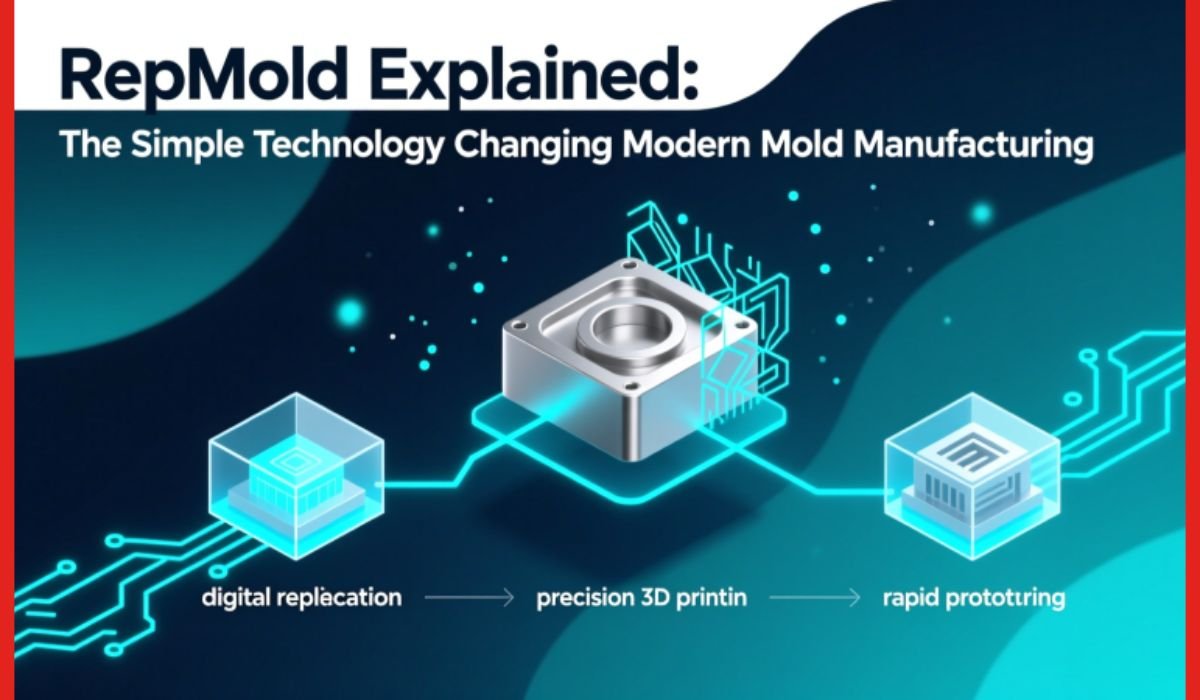

RepMold Explained: The Simple Technology Changing Modern Mold Manufacturing

Introduction: Why Mold Manufacturing Needed a Smarter Solution

In the fast-paced world of manufacturing, time, precision, and cost efficiency are everything. But for decades, mold manufacturing has remained stuck in time—relying on traditional techniques that are slow, expensive, and difficult to customize. As industries evolve and the demand for faster product development grows, these outdated processes are becoming a bottleneck. That’s where RepMold comes in.

RepMold is not just another upgrade—it’s a complete shift in how molds are designed, built, and used across industries. With digital innovation at its core, this new approach allows manufacturers to work faster, smarter, and more sustainably. If you’re wondering how RepMold works, what makes it different, and why it’s being called the future of mold technology, this guide will explain it all in simple terms.

Quick Bio Information

RepMold Launch Year

2024

Technology Type

Digital Mold Manufacturing

Key Components

CAD, 3D Printing, Automation

Primary Industries

Automotive, Aerospace, Electronics, Healthcare

Main Benefits

Speed, Precision, Cost Reduction, Sustainability

Compatible Materials

Polymers, Resins, Some Metals

Ideal For

Custom Manufacturing, Rapid Prototyping

Part of Industry 4.0?

Yes

Supports Smart Factory Systems

Yes

Used By

Global Enterprises and Small Manufacturers

Based On

Additive Manufacturing and Digital Design

What Is RepMold? A Simple Explanation Of The Technology

RepMold is an advanced mold manufacturing technology that blends computer-aided design (CAD), 3D printing, and automation to create high-precision molds faster and more efficiently than traditional methods. It replaces manual tooling and complex machining processes with digital workflows that are faster, cheaper, and more customizable.

Instead of relying on slow subtractive manufacturing, RepMold often uses additive manufacturing processes—such as 3D printing—to build molds layer by layer. These molds can be used in various industries like automotive, aerospace, electronics, and consumer goods. Whether you’re making a car part or a plastic casing for a device, RepMold allows for high-quality, custom molds without the long wait.

What sets RepMold apart is its ability to rapidly produce functional mold prototypes and final molds with exceptional detail, all while reducing human error. For manufacturers of all sizes, that means faster turnarounds, better products, and more room to innovate.

How Traditional Mold Manufacturing Works And Where It Falls Short

Traditional mold making typically involves lengthy processes like CNC machining, electrical discharge machining (EDM), and manual finishing. These methods can take weeks or even months, depending on the complexity of the mold. Manufacturers begin by creating a detailed blueprint, followed by milling or cutting steel or aluminum blocks into the required mold shape.

While reliable, these methods have major drawbacks. First, they are expensive—requiring high-end machinery and skilled technicians. Second, they are slow. Any changes in design mean starting over or making complicated adjustments. Lastly, complex geometries are often limited by the physical capabilities of the tools.

For businesses needing speed and flexibility, especially in today’s on-demand market, traditional mold manufacturing just can’t keep up. This is why the industry has been eager for a better solution—and why RepMold has arrived at just the right time.

Inside RepMold: The Core Technologies That Make It Work

RepMold operates at the intersection of several breakthrough technologies. At the heart of the system is CAD software, which allows designers to create precise digital models of the mold. These files can then be directly fed into 3D printers or digital fabrication machines to produce the mold without going through manual machining stages.

The 3D printing process used in RepMold supports complex geometries that would be almost impossible to achieve with traditional methods. Additive manufacturing also means minimal material waste—since you’re building only what you need, rather than cutting away from a block of metal.

Automation plays a vital role as well. Robotic arms and automated quality checks can monitor and adjust the manufacturing process in real time, ensuring consistent quality. RepMold is also compatible with other Industry 4.0 tools, including data analytics and smart sensors, making it part of a larger move toward fully digitized manufacturing.

Key Advantages Of RepMold Over Traditional Mold-Making

RepMold’s biggest strength is speed. It drastically reduces the time required to go from design to production. Prototypes that used to take weeks can now be ready in days, if not hours. This fast iteration process allows companies to test more ideas and bring products to market faster.

Another clear advantage is cost savings. By minimizing labor, reducing material waste, and lowering energy use, RepMold helps manufacturers cut expenses without sacrificing quality. The technology also supports greater customization, allowing businesses to create small batches of highly specialized molds without the traditional overhead.

Because of its precision, RepMold also improves the quality of the final product. Molds are more consistent, with fewer defects. This not only reduces waste but also improves customer satisfaction and brand reputation.

Real-World Examples: How Companies Are Using RepMold Today

Across the world, companies are already seeing results with RepMold. In the automotive sector, one leading car manufacturer cut its mold development time by 50% by switching to RepMold. This allowed the company to introduce new parts more quickly, giving it an edge in a competitive market.

An aerospace company faced delays due to flaws in their traditional mold processes. After adopting RepMold, they reduced production delays by 30% and significantly lowered their defect rates. The ability to create complex and lightweight parts was especially valuable in their safety-critical environment.

Even small electronics manufacturers are reaping benefits. One firm used RepMold to produce rapid tooling for its device housings. What previously took months was done in just a few weeks—accelerating product launches and helping the business stay ahead of fast-moving tech trends.

RepMold In Industry 4.0: A Perfect Fit For The Smart Factory Era

RepMold is more than just a tool—it’s a smart manufacturing solution that fits perfectly within the Industry 4.0 framework. By combining automation, data analytics, and digital design, RepMold allows factories to become more connected, responsive, and intelligent.

Manufacturers can now gather real-time data from the mold-making process, use that data to predict potential issues, and make adjustments on the fly. This means better quality control, faster decision-making, and fewer surprises.

In a smart factory environment, RepMold works alongside robotics, machine learning systems, and IoT sensors to create a seamless production line. The result is a more agile operation that can respond to market changes instantly—whether that’s a surge in demand or a shift in customer preferences.

Challenges And Limitations Of RepMold

Despite its advantages, RepMold is not without challenges. One of the biggest barriers is the upfront cost. Investing in the necessary equipment, software, and training can be expensive for smaller companies. However, the long-term savings often make up for this initial hurdle.

Another limitation is the range of materials that can be used. While RepMold supports a growing list of advanced polymers and metals, not every material used in traditional molds is yet compatible with additive manufacturing. This can limit its application in highly specialized industries.

There’s also a learning curve involved. Teams need training to use digital design tools effectively and understand how to optimize designs for 3D printing. But as more companies adopt the technology and best practices are established, these barriers are becoming easier to overcome.

The Future Of Mold Manufacturing: What RepMold Might Look Like In 5–10 Years

Looking ahead, RepMold is expected to become even smarter and more capable. Advances in artificial intelligence could allow the system to automatically optimize mold designs based on product requirements, cutting development time even further.

Eco-friendly materials are also on the horizon. As sustainability becomes a bigger priority, RepMold may integrate biodegradable or recycled materials into its workflows—making mold manufacturing cleaner and greener.

The integration of blockchain technology could add a new level of transparency to the supply chain. Manufacturers would be able to trace every step of the mold-making process, ensuring accountability and compliance with regulations.

RepMold’s future lies in its ability to evolve. As digital tools become more powerful and accessible, the technology is expected to reach more industries, more countries, and more small businesses that previously couldn’t afford advanced manufacturing solutions.

Who Should Use RepMold? A Simple Guide For Businesses And Manufacturers

RepMold is not just for big companies. While large-scale manufacturers may have been early adopters, small and mid-sized businesses are starting to realize its value. If your business creates plastic parts, metal components, or specialized tools, RepMold can likely help you do it faster and better.

It’s especially useful for industries that rely on fast product development cycles, such as consumer electronics, medical devices, and automotive suppliers. Businesses that do custom work or operate in niche markets also benefit from the flexibility and speed of RepMold.

Ultimately, if your company wants to reduce production time, lower costs, improve quality, and stay competitive in a changing market, it’s worth exploring how RepMold can fit into your operations.

Conclusion: Why RepMold Is Becoming The New Standard In Modern Manufacturing

RepMold represents a turning point in mold manufacturing. It brings together speed, accuracy, flexibility, and sustainability in a way that traditional methods simply can’t match. For companies navigating modern challenges—tight deadlines, rising costs, and growing complexity—RepMold offers a clear path forward.

As more manufacturers embrace smart production methods, RepMold is set to play a key role in the industry’s evolution. Whether you’re a global enterprise or a small business ready to scale, RepMold is a tool that can help you do more, do it faster, and do it better. In a world where every second counts, RepMold is not just a technology—it’s a game-changer.

FAQs About RepMold

What Is RepMold?

RepMold is an advanced mold manufacturing technology that uses digital tools like CAD and 3D printing to create high-quality molds faster and more efficiently than traditional methods.

How Does RepMold Reduce Costs?

It minimizes waste, shortens production times, and reduces labor costs through automation and digital workflows, leading to significant savings over time.

Is RepMold Only For Large Factories?

No, RepMold is highly adaptable and can be used by small businesses, startups, and medium-sized manufacturers looking to improve efficiency.

Which Industries Use RepMold The Most?

Industries like automotive, aerospace, healthcare, electronics, and consumer goods use RepMold for its speed, precision, and ability to handle complex designs.

Does RepMold Support Sustainable Manufacturing?

Yes, RepMold reduces material waste, supports energy efficiency, and is increasingly integrating eco-friendly materials for greener production.

Can RepMold Create Complex Designs?

Absolutely. RepMold excels at producing molds with intricate geometries that traditional methods often struggle to replicate.

What Is The Future Of RepMold?

RepMold is expected to evolve with AI, smart materials, and blockchain integration, making it an essential part of the future of digital manufacturing.

People Also Read: MySDMC SSO: A Simple Guide to the Login System Every Student Should Know

Celebrity9 months ago

Celebrity9 months agoMelanie Sergiev: Bulgarian Athlete and Drew Lynch’s Wife – Her Inspiring Life Story

Celebrity5 months ago

Celebrity5 months agoVictoria Elizabeth Bateman: The Woman Behind Jason Bateman’s Success

Celebrity5 months ago

Celebrity5 months agoWho Is Nimesh Patel Wife? Everything to Know About Amy Havel Patel

Celebrity9 months ago

Celebrity9 months agoWho Is Heidi May? Everything You Need to Know About Henry Rollins’ Wife and Her Creative Work